- Home

- About Us

- About Us

- factory

- Team Style

- Honor

- Why Chooes Us

- Products

- Products

- Impact modifiers

- Flame Retardant

- Brightening Agent

- Stiffness Agent

- Color Pigment

- Color Masterbatch

- Nucleating Agent

- MFI Modifier

- Anti-cold Agent

- UV Stabilizer

- Light Dispersing Agent

- Biodegradable Agent

- anti-shrinkage agent

- Heat Resistant Agent

- Others

- moisture absorbent

- Meltblown PP Granule

- EVA Granule

- Antimicrobial

- Compatibilizer

- Applications

- News

- News

- Cases

- Cases

- FAQ

- FAQ

- Global Market

- Global Market

- Contact us

- Contact us

Plastic additive uv stabilizer manufacturer

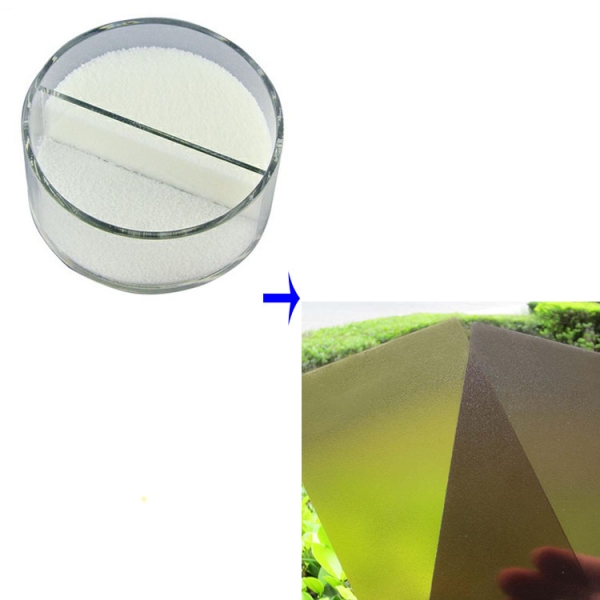

1.the uv stabilizer highly ensure good color consistency of plastic polymers in direct sunshine

More Product Details

Plastic additive uv stabilizer manufacturer

---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Description for uv stabilizer

1. It is a light stabilizer with good performance, capable of absorbing the UV radiation of240-340 nm wavelength with the characteristics of light color, It can protect the polymer to its maximum extent, helps to reduce the color changing problem.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Specification for uv stabilizer

Appearance: Light yellow needle-like powder

Content : ≥99%

Melting Point : 47-49°C

Ash : <0.1%

Light Transmittance: 450nm>90% 500nm>95%

model number

A-438

brand number

ALLGONG. ARGIOPE

effective substance content

100%

dosage

0.2%--0.6%

application

PP PE PVC .PPS PPO etc.

warranty

3 years

-----------------------------------------------------------------------------------------------------------------------------------------------

Usage for uv stabilizer

Adding A-438 when mixing , first mix the plastic raw material even with diffusion agent or white mineral oil, then mix them for 8-10 minutes, after fully mixed, roasted material .then it can be used for extrusion, injection molding or blow molding.

-----------------------------------------------------------------------------------------------------------------------------------------------

Application for uv stabilizer

It is widely applied to PE,PVC,PP,PS,PC organic glass, polypropylene fiber, etc.

It can be applied to plastic containers and food packing boxes as packaging materials, provide them good light-stabilizing effect.

---------------------------------------------------------------------------------------------------------------------------------------------

packing & payment & delivery

| packing | Paper-Poly Pouch or Carton Box (net weight 25kg/bag). |

| Storage | It should be stored in a shady and dry storehouse, it is shelf life is three year |

| payment | L/C,T/T, Western Union,Paypal. |

| Delivery | 1-2 days for sample, 3-15 days for bulk order. |

| MOQ |

1 KG |

---------------------------------------------------------------------------------------------------------------

certification

(1)Food Safety standard;

(2) Japanese Food and Toy Packaging STPART3: 2002 standard;(3) EU REACH and PHAS standards;

(4) EU ROHSEZT121 standards;

(5) EU Toys PHTHALATES (phthalates) standard;

(6) EU Toys EN71.3 standards;

(7) EN1122 standard.

---------------------------------------------------------------------------------------------------------------

CONTACT PERSON

Lyen

Mob/Wechat/WhatsApp: 86-13417457738

Skype: huang.lyen